Подробнее

PGS 350/450 R Canter for Sawmill Line

Sawmill line with combined Chipper-Canter

Wide range of standard chip blocks sizes with stable geometry.

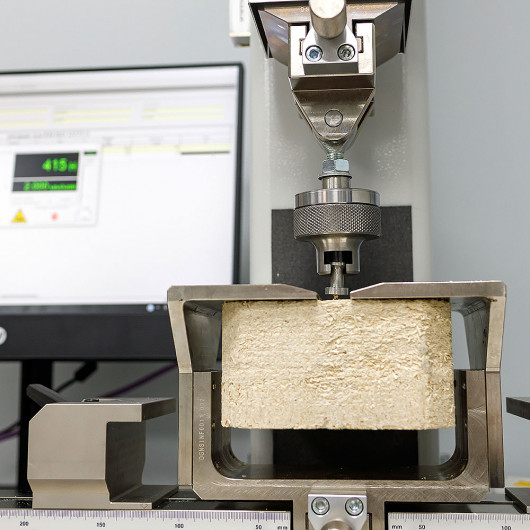

OSKO-INVEST has been manufacturing pressed blocks for pallets since 2022. The Company operates up-to-date and high-tech equipment IMAL-PAL (Italy). Computerized systems enables obtaining pressed blocks with desired shape with stable parameters and constant quality. Each block automaticaly controlled by weight, density and dimensions.

The nail retraction resistance has an average value of at least 5.5 kN.

Our advanced drying process prevents pest infestation and mould.

The durability of pressed blocks is higher than one of lumber brackets. Density exceeds 600 kg/m³.

Protected against fungi, mold and insect pests.

High performance resistance to temperature fluctuations and humidity.

The blocks manufacturing employs urea formaldehyde resin, which provides protection against moisture destruction.

The company stands for the efficient and resource-saving use of timber. All residual materials after woodworking (sawdust and wood chips) are used to produce pallet blocks up to 70,000 m³ per year.

We produce lumber with maximum efficiency and economy of natural resources, which are able to satisfy the needs with the highest quality requirements.

Wide range of standard chip blcok sizes with stable geometry 70х70 mm, 75х75 mm, 95х95 mm, 78х98 (СР) mm, 98х143 (epal) mm, 143х143 (epal) mm

See more

Pallet boards of high quality softwood with a thickness from 15 mm and with length up to 4000 mm.

See more

OSKO-INVEST offer for warehouses, manufacturing and logistics companies kits for pallets assembling of various sizes and load capacities.

See more